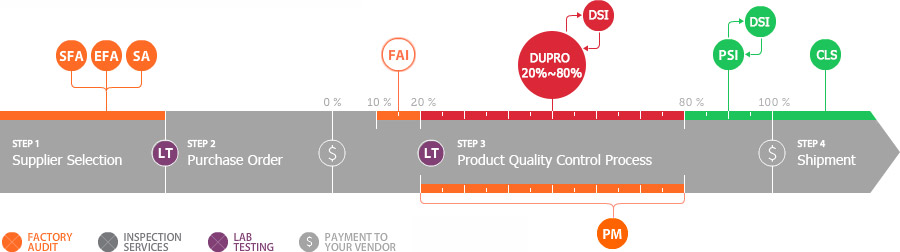

OUR SERVICE FLOW IN YOUR PURCHASING PROCESS

What is BoNiSin’s Quality Control Solutions?

A. Inspection Services Solutions:

- During Production Inspection (DUPRO): To improve quality during on line inspection (Performed when 20~80% of production is completed).

- Pre-Shipment Inspection (PSI): Guarantee the conformity of products meet your specifications (Should be performed when 80% of production is completes).

- Production Monitoring (PM): To verify that the factory operators have the correct production processes to produce your product.

- Sorting Inspection (SI): To sort out all the defect parts as possible.

- Container Loading Supervise (CLS): To ensure punctual & securely loaded.

B. Factory Audit Solutions:

- Simple Factory Audit (SFA): Check the needed certificates and licenses for the specific factories.

- Extensive Factory Audit (EFA): Our vendor audit process will help you match production capability, performance, and professionalism with your expectations and requirements, including check the supplier is legal and confirm your factory has the production capacity and ensure quality.

- Social Audit (SA): To protect employees and your brand.

- Environmental Audit (EA): To ensure that you are doing business with factories in which environment regulations and international environment standards are respected. The Environmental Audit in China and Asia assesses a factory as per ISO 14001.

- C-TPAT Audit(C-APAT): Our qualified auditors independently assess the security and commercial processes of your business partners. We go on-site and get the information you need to ensure C-TPAT compliance.

C. Lab Testing & Compliance

- Laboratory Partners

- Common Laboratory Tests